HHM - MODULARE ADSORPTIONSLUFTTROCKNER

der PNEUMATIC Products Raupach GmbH

Luftdurchsätze von 5 m³/h bis 300 m³/h

Der NEUE modulare Adsorptionslufttrockner der HHM-Serie von Hankison zeichnet sich in verschiedenen Branchen dadurch aus, dass er Druckluft von höchster Qualität gewährleistet und Drucktaupunkte von -40 °C bis -70 °C für kritische Anwendungen bietet.

Dank der niedrigen PED-Kategorie (Druckgeräterichtlinie, PED 97/23/EG) tragen HHM-Trockner dazu bei, die Kosten im Zusammenhang mit der regelmäßigen obligatorischen Überprüfung von Druckgeräten zu minimierenAusrüstung. Darüber hinaus vereinfacht ihr modulares Design nicht nur die Erstinstallation, sondern macht auch zukünftige Erweiterungen oder Modifikationen problemlos möglich.

Die HHM-Serie verfügt für ausgewählte Modelle über unser fortschrittliches Energiemanagementsystem (EMS) und bietet einen konservativen Druckabfall von 0,18 barg mit möglicher Spülreduzierung bei Druckluftbedarf (Ein-/Aus-Laststeuerung).

Abhängig von der angewandten Vor- und Nachfiltration sind diese Trockner in der Lage, die Anforderungen verschiedener Anwendungen zu erfüllen, darunter die Pharma-, Chemie-, Lebensmittel- und Getränkeindustrie und mehr

Die neuen modularen Adsorptions-Drucklufttrockner von HHM verfügen über mehrere Designlösungen, die ihre Leistung verbessern und sich in echten Vorteilen für Sie und Ihre Kunden niederschlagen

Mikroprozessor (HHM 5 – 25)

- Einfach zu bedienen – Intuitive Benutzeroberfläche, einfache Navigation

- Kompakt, passend für kleine Einheiten

- Zykluszeitanzeige

- Trocknungs-/Regenerationsanzeige für den rechten/linken Turm

Neue digitale Steuerung – Warnmeldungen zur vorbeugenden Wartung

- Warnungen basierend auf den Betriebsstunden

- Wartungswarnungen für:

- Filterelementwechsel

- Austausch des Schalldämpfers

- Ventilaustausch

- Trockenmittelwechsel

- Taupunktsensor-Service (nur mit EMS)

Proaktive Wartung für Trocknerzuverlässigkeit und Kundenverfügbarkeit.

Konnektivität

- Modbus-fähig

- RS-485-Kommunikation:

- Einfachere Integration in eine Vielzahl von DCS-Systemen

- Fernalarm

- Kommuniziert Sammelalarm über Modbus

Kompressor-Interlock-Funktion

- Reduzieren Sie die Zeitdauer des Spülzyklus basierend auf dem Druckluftbedarf

- Die Steuerung überwacht die Zyklusrate des Ladens/Entladens des Luftkompressors, um die Spülzeit effektiv zu verkürzen (wenn mehr als ein Kompressor an HHM angeschlossen ist, muss das Ein-/Aus-Relais des Kompressors mit dem niedrigsten Drucksollwert verwendet werden).

EMS-Option (Energiemanagementsystem)

Bei dieser Option ist das Gerät mit einem hochpräzisen Taupunktsensor ausgestattet, der an den digitalen Controller angeschlossen ist. EMS passt den Betrieb des Trockners entsprechend der vom Sensor gemessenen Taupunkttemperatur der Auslassluft an (EMS übernimmt die Entlastungssperrfunktion des Kompressors). Der Return of Investment von EMS kann weniger als ein Jahr betragen, wodurch die Gesamtbetriebskosten gesenkt werden.Zuverlässigkeit, lange Lebensdauer (Wartung alle 3 Jahre)

- Bewährte pneumatische Spülventile

- Magnetsteuerventil

Geringer Lärm am Einsatzort

- Spülschalldämpfer < 75 dBA

Schnelles visuelles Lesen

- Manometer

Sicher, einfach zu bewegen und zu installieren

- Füße mit Gabelstapler-Proviant

- Schutz von Schalldämpfern

Model | Maße | Gewicht | ||

Tiefe | Breite | Höhe | ||

mm | kg | |||

HHM 5 | 212 | 238 | 423 | 11 |

HHM | 212 | 238 | 823 | 18 |

HHM 25 | 212 | 238 | 1073 | 27 |

HHM 40 | 405 | 475 | 968 | 44 |

HHM 55 | 405 | 475 | 1118 | 50 |

HHM 70 | 405 | 475 | 1318 | 60 |

HHM 100 | 405 | 475 | 1673 | 73 |

HHM 150 | 405 | 475 | 1873 | 90 |

HHM 200 | 495 | 536 | 1705 | 177 |

HHM 250 | 495 | 536 | 1905 | 180 |

HHM 300 | 495 | 536 | 1905 | 188 |

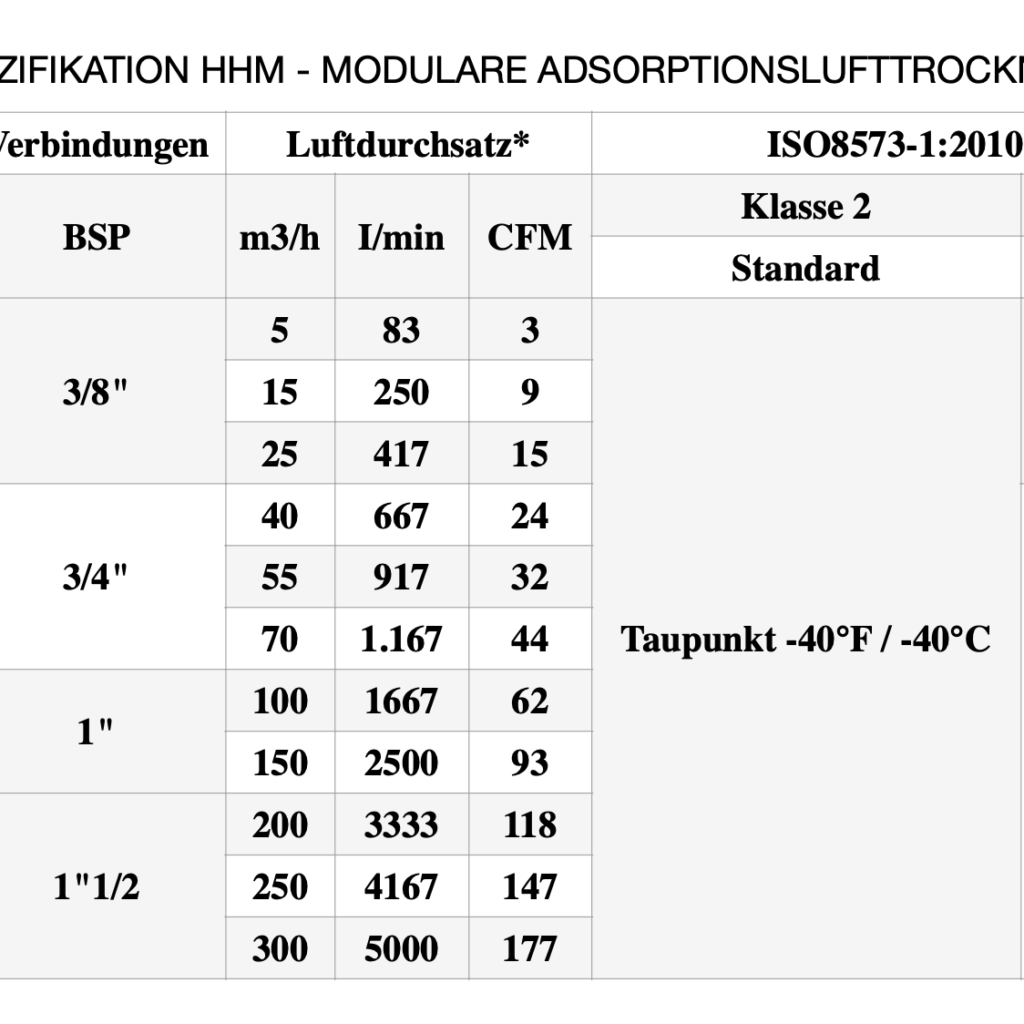

Model | Code | Verbindungen | Luftdurchsatz* | ISO8573-1:2010 Water content | |||

BSP | m3/h | I/min | CFM | Klasse 2 | Klasse 1 | ||

Standard | Optional | ||||||

HHM 5 | 32300000 | 3/8″ | 5 | 83 | 3 | Taupunkt -40°F / -40°C | Nicht verfügbar |

HHM | 32300005 | 15 | 250 | 9 | |||

HHM 25 | 32300010 | 25 | 417 | 15 | |||

HHM 40 | 32300015 | 3/4″ | 40 | 667 | 24 | Taupunkt -100°F/-70°C | |

HHM 55 | 32300020 | 55 | 917 | 32 | |||

HHM 70 | 32300025 | 70 | 1.167 | 44 | |||

HHM 100 | 32300030 | 1″ | 100 | 1667 | 62 | ||

HHM 150 | 32300035 | 150 | 2500 | 93 | |||

HHM 200 | 32300040 | 1″1/2 | 200 | 3333 | 118 | ||

HHM 250 | 32300045 | 250 | 4167 | 147 | |||

HHM 300 | 32300050 | 300 | 5000 | 177 | |||

- Die Leistungen beziehen sich auf eine Luftansaugung von 20 °C (68 °F), 1 bar (14,5 psig) und die folgenden Betriebsbedingungen: 7 bar (100 psig) Arbeitsdruck, -40 °C (-40 °F) Drucktaupunkt , 25 °C (77 °F) Umgebungstemperatur, 35 °C (95 °F) Drucklufteinlasstemperatur.

NPT-Anschlüsse sind auf Anfrage erhältlich. Kontaktieren Sie uns, um detaillierte Informationen zu Korrekturfaktoren und anderen technischen Daten zu erhalten.

Kompressor-Interlock-Funktion

- Reduzieren Sie die Zeitdauer des Spülzyklus basierend auf dem Druckluftbedarf

- Die Steuerung überwacht die Zyklusrate des Ladens/Entladens des Luftkompressors, um die Spülzeit effektiv zu verkürzen (wenn mehr als ein Kompressor an HHM angeschlossen ist, muss das Ein-/Aus-Relais des Kompressors mit dem niedrigsten Drucksollwert verwendet werden).

EMS-Option (Energiemanagementsystem)

Bei dieser Option ist das Gerät mit einem hochpräzisen Taupunktsensor ausgestattet, der an den digitalen Controller angeschlossen ist. EMS passt den Betrieb des Trockners entsprechend der vom Sensor gemessenen Taupunkttemperatur der Auslassluft an (EMS übernimmt die Entlastungssperrfunktion des Kompressors). Der Return of Investment von EMS kann weniger als ein Jahr betragen, wodurch die Gesamtbetriebskosten gesenkt werden.Zuverlässigkeit, lange Lebensdauer (Wartung alle 3 Jahre)

- Bewährte pneumatische Spülventile

- Magnetsteuerventil

Geringer Lärm am Einsatzort

- Spülschalldämpfer < 75 dBA

Schnelles visuelles Lesen

- Manometer

Sicher, einfach zu bewegen und zu installieren

- Füße mit Gabelstapler-Proviant

- Schutz von Schalldämpfern

BITTE BEACHTEN SIE DAS DIE ABMESSUNGSTABELLEN IN DER MOBILEN ANSICHT NICHT ANGEZEIGT WERDEN KÖNNEN DURCH DIE GRÖSSE DER TABELLEN.

MIT IHREM COMPUTER KÖNNEN SIE AUF ALLE ABMESSUNGSTABELLEN ZUGREIFEN.

BITTE BEACHTEN SIE!

DAS DIE SPEZIFIKATIONSTABELLEN IN DER MOBILENANSICHT NICHT ANGEZEIGT WERDEN KÖNNEN.

ALTERNATIV KÖNNEN SIE DIE SPEZIFIKATIONSTABELLE ODER PRODUKTFLYER ALS PDF HERUNTERLADEN.

- Hier finden Sie alle vorhandenen PDF Dateien zum Produkt Hankinson - HHM - MODULARE ADSORPTIONSLUFTTROCKNER

Service Teile oder Support anfordern

Für Fragen zu bestehenden Kältetrockner Anlagen, Ersatzteile oder unseren Service schreiben Sie uns einfach an!

Firmenanschrift

Pneumatic Products Raupach GmbH

Druckluft- und Adsorptionstechnik

Aschaffenburger Straße 5

D-64546 Mörfelden-Walldorf

© Copyright 2024 Pneumatic Products Raupach GmbH. All right reserved.